Electronics is a constant presence in our lives and in the industrial field it is now an essential component of plants; electronics have made it possible to run the production lines much easier, improve their performance, optimizing the operation of the machines through an automatic adjustment of the process parameters, without the need for operator intervention, thanks to the continuous monitoring of the operating conditions on the HMI operator panel (synoptic).

All this has allowed, in addition to the reduction of the staff employed to run the plants, a general improvement in working conditions and above all a quantitative and qualitative increase in production, as the automatic control of the process parameters guarantees the maintenance of the level of product quality over time and with varying environmental conditions.

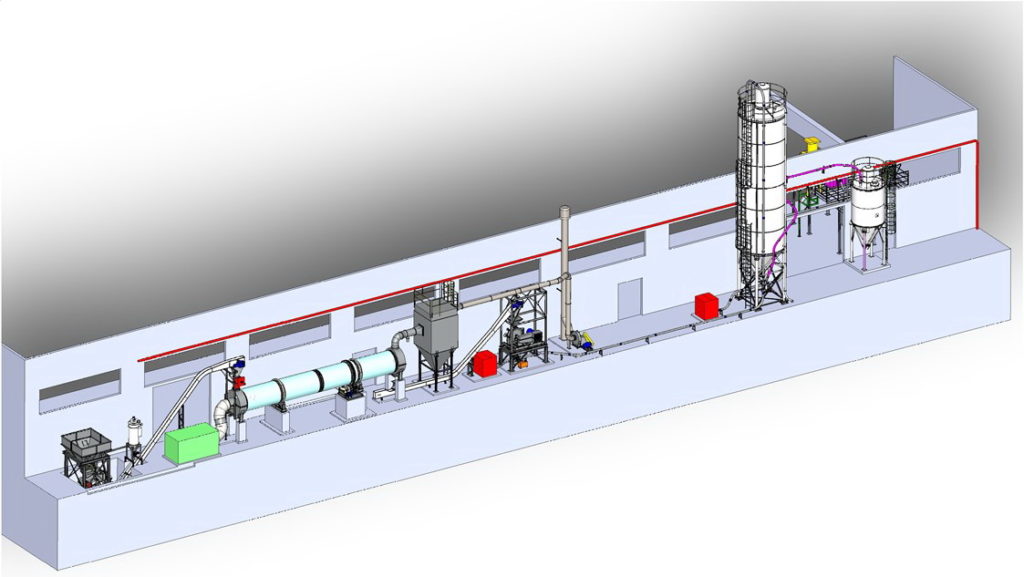

Pennati Costruzioni Meccaniche is committed to creating a gypsum burning and grinding line dedicated to the production of premixed insulating panels of various kinds.

It is a complete line, supplied “turnkey”, which fulfills the strict requirements of high automation requested by the customer. The process line has been entirely designed, built, tested and put into operation by our company.

The plant includes the Hammer mill that reduces the size of the raw gypsum from quarry from about 150 mm to 8 mm, a chain conveyor that introduces the product into the rotary drum kiln and another chain conveyor that takes up the terracotta unloaded from the furnace and feeds the horizontal axis Refining mill; the Refining mill ensures that a fineness of 150 microns is reached, then the gypsum is conveyed, through a pneumatic transport system, to the storage silo. The second chain conveyor also picks up the product discharged from the filter.

The fan at the rear of the plant, which keeps the entire line in suction and which at the same time guarantees the flow of hot gases inside the kiln, discharges the exhausted gases into the atmosphere, suitably filtered, now at a low temperature and at a high moisture content, being burdened with the crystallization water removed during the calcination process inside the furnace.

The process control also provides for the control of the enthalpy conditions of the flue gases in the chimney, in order to avoid the formation of condensation.

The hot air generator that supplies the thermal energy for calcination of the gypsum includes the presence of a methane burner with continuous flame modulation: the process control in this case is aimed, as well as guaranteeing the constancy of the product quality, to optimize fuel consumption.

In this regard, it is worth pointing out that all the “hot” surfaces have been suitably insulated. The operation of the system, as mentioned, is controlled by a logic PLC, which automatically operates the entire system.The plant is able to produce multiple varieties of gypsum so that it always has the ideal characteristics for each different type of panel in production: the corresponding “recipe” has therefore been set for each type, which is pre-selected from time to time by the operator before starting the plant.

The presence of a technician is aimed at monitoring the operation of the system through the HMI operator panel (touch panel), which is on-line in the company network, so that the operator can conveniently start and monitor the operation of the system from the offices.